Limestone

- Limestone is a sedimentary rock primarily composed of calcium carbonate(CaCO3) in the form of the mineral calcite. It is typically formed from marine organisms such as coral and shells, which accumulate on the sea floor and are compressed over millions of years.

- Limestone’s versatility and abundance make it a crucial mineral in various industrial applications, driving economic development and technological advancements across multiple sectors.

- Limestone’s role in cement manufacturing is fundamental, providing the essential ingredients for the chemical reactions that produce the binding properties of cement.

- Limestone is a key ingredient in the glass manufacturing process. Its primary role is to act as a stabilizer, helping to improve the properties and quality of the final glass product.

Key Characteristics:

- Composition: Mainly calcium carbonate with minor amounts of silica, clay, silt, and sand.

- Appearance: Typically white, gray, or light-colored, though impurities can give it various hues.

- Texture: Fine to coarse-grained, depending on the size of the calcite crystals.

Formation and Distribution:

- Limestone forms in clear, warm, shallow marine waters and is prevalent in regions with historical marine environments. Major deposits are found in countries like the USA, China, India, and parts of Europe.

Mechanical Properties:

- Density: Indicates the compactness and suitability for construction purposes.

- Porosity: Affects durability and suitability for building materials.

Color:

- Color variations can indicate the presence of different impurities, affecting its desirability for certain uses, such as in the building stone industry.

Reactivity:

- The reactivity of limestone with acids, especially in flue gas desulfurization and water treatment applications.

Physical Properties:

- Hardness: Measured by the Mohs scale, which influences the usability in different applications.

- Grain Size and Texture: Fine-grained limestone is often preferred for certain applications like cement and glass manufacturing.

- Hardness: Relatively soft, with a Mohs hardness of 3.

- Density: Ranges from 2.3 to 2.7 grams per cubic centimeter.

- Solubility: Soluble in acidic solutions, which leads to features like caves and karst landscapes.

Types of Limestone:

- Quick Lime

- Fat Lime

- Hydraulic Lime

| S.No | List of Parameters | Result in (%) | |

|---|---|---|---|

| 1 | Calcium Carbonate | CaCo3 | 90 - 98 % |

| 2 | Iron Oxide | Fe2O3 | 0.1 - 0.5 % |

| 3 | Alumina Oxide | Al2O3 | 0.1 - 0.5 % |

| 4 | Silica | SiO2 | 0.5 – 2 % |

| 5 | Magnesium Carbonate | MgCo3 | 1 – 5 % |

| 6 | Sulfur | S | < 0.05 % |

Industrial Uses of Limestone:

1. Construction and Building Materials:

- Aggregate: Used in concrete and road construction.

- Dimension Stone: Cut into blocks and slabs for use in buildings.

- Cement Production: Major component in the manufacture of Portland cement.

2. Chemical Industry:

- Lime Production: Heating limestone produces lime (CaO) used in steel manufacturing, water treatment, and flue gas desulfurization.

- Glass Manufacturing: Acts as a stabilizer in glass production.

- Filler Material: Used in paints, plastics, and rubber to enhance durability and strength.

3. Agriculture:

- Soil Conditioning: Neutralizes acidic soils and provides calcium for plant growth.

- Animal Feed: Added to poultry feed to ensure adequate calcium intake.

4. Environmental Applications

- Water Treatment: Removes impurities and balances pH levels.

- Flue Gas Desulfurization: Captures sulfur dioxide emissions from power plants.

- Waste Treatment: Used in sewage treatment and sludge treatment processes.

5. Steel Industry

- Fluxing Agent: Removes impurities during steel production.

6. Other Uses

- Paper Industry: Acts as a filler and coating material to improve brightness and opacity.

- Pharmaceuticals: Used as a calcium supplement and in antacid

- Cosmetics: Used as a filler and stabilizer in various cosmetic products.

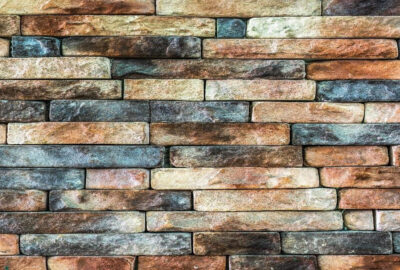

Reference Images:

Product Images

Packing Available